FloorKIT — is a pre-assembled factory floor slab with an insulated steel base and a ready concrete screed, designed for the modular assembly of buildings and compatible with the KARKASYS system. The slab combines the rigidity of the metal profile, thermal and sound insulation, geometric precision, and ease of installation.

Advantages

• High load-bearing capacity combined with low self-weight.

• Factory accuracy and quality of all elements.

• Reduction of installation times by 3–4 times compared to prefabricated and by dozens of times compared to monolithic slabs.

• High energy efficiency due to the integration of basalt insulation.

• Possibility of integrating engineering channels and installation fittings at the production stage.

• Full compatibility with PanelKIT panels and CoreFRAME beams, including the use of VU connector.

Installation

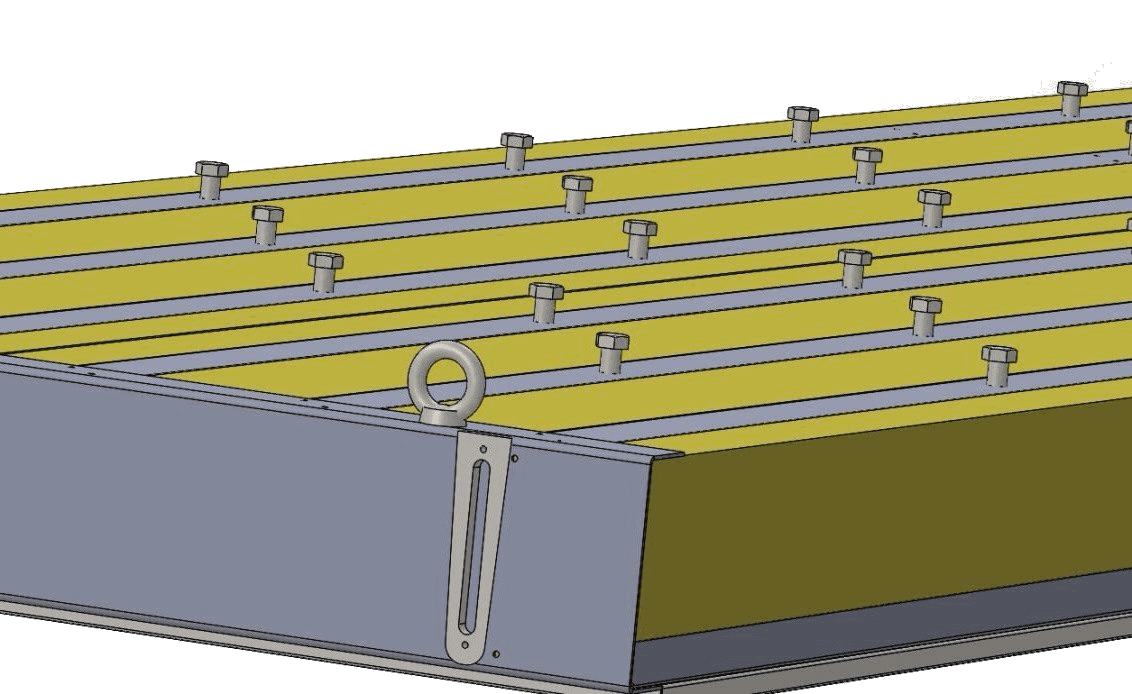

• Lifting and positioning is carried out using eye bolts.

• The slab is installed without wet processes, welding, and formwork.

• Ensures a precise fit in the modular frame CoreFRAME or between the load-bearing beams of traditional frame buildings or in buildings with load-bearing walls.

• If necessary, it can be partially integrated into the monolithic ceiling scheme.

Dimensions and characteristics

• Slab width — 1200 mm (standardized for modular construction).

• Length — as per the project (within transportation dimensions).

• Concrete grade C30.

• Regulatory load — residential building.

Construction

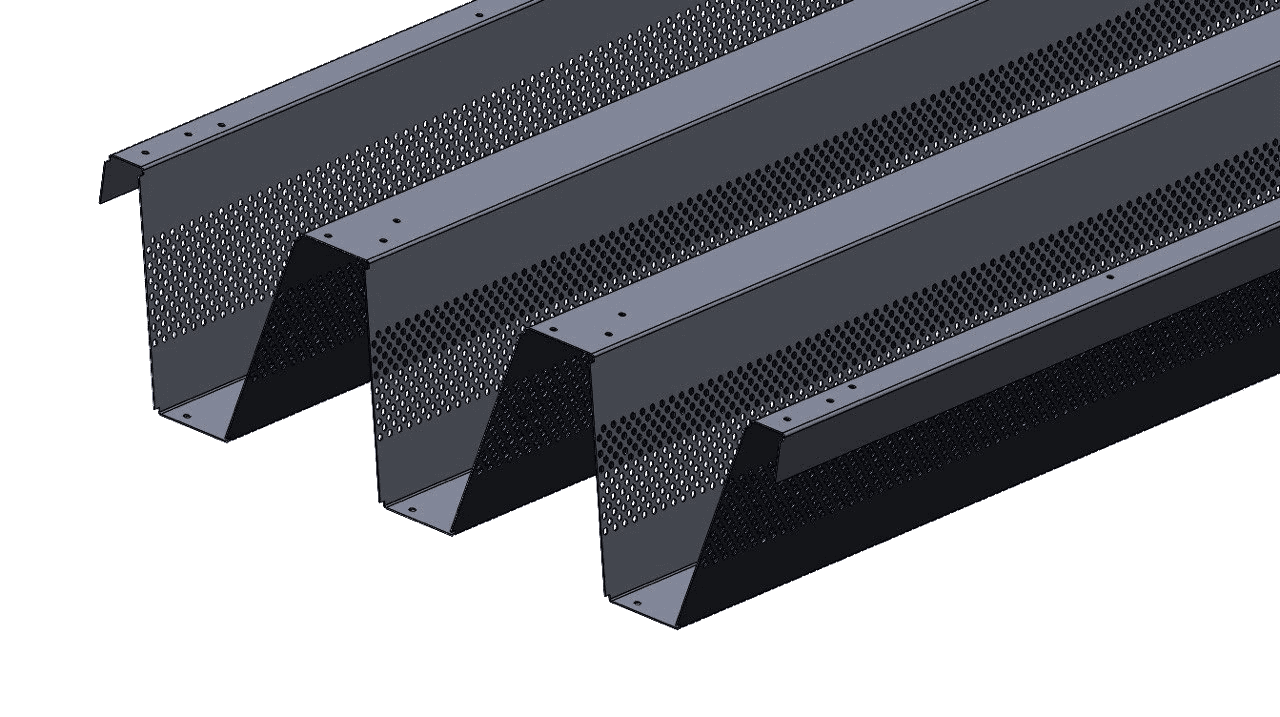

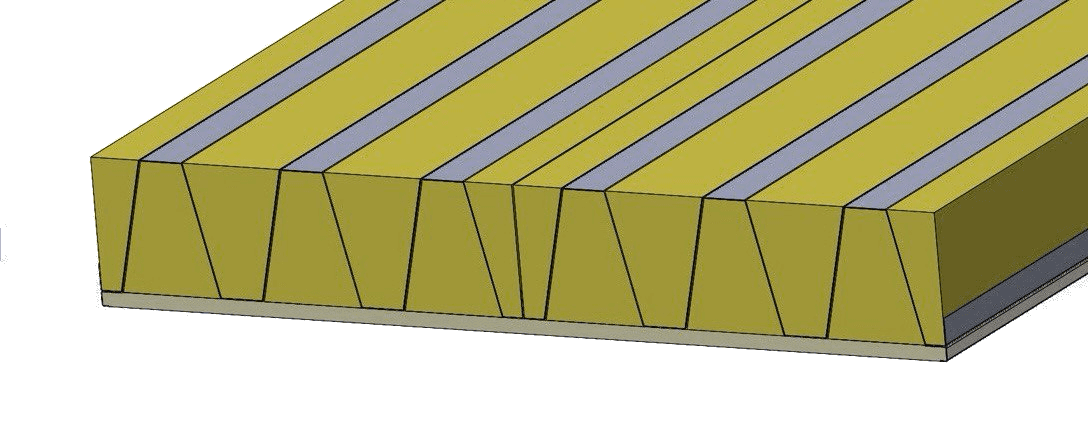

• The load-bearing part is made of trapezoidal metal profiles manufactured from S355 steel, featuring perforations to enhance thermal and acoustic insulation properties.

• The end profiles are rigidly connected to the side channels, on which the mating parts of VU connectors are installed. Nuts welded to the inner surface of the upper shelf of the trapezoidal profile, with a mounting step of 300×300 mm and a mounting height of 25–30 mm, serve to ensure a reliable connection of the load-bearing element of the slab with the concrete screed.

• Basalt plates with a density of 125 kg/m³ are installed in the lower and upper waves of the trapezoidal profile.

• The upper surface is filled with a concrete screed (up to 100 mm), reinforced with welded mesh Ø6 mm (cell size 150×150 mm).

• The formwork necessary for pouring is secured to the frame via standard nuts at the corners, designed for eye bolts, thus eliminating the need for individual molds.